Address

BIOWONDER, 789 Anandapur, Suite No. - 1402, 14th Floor, Kolkata - 700107

Work Hours

Monday to Saturday: 10AM - 6PM

Faster lead times, an expanding product line, a state-of-the-art factory and a proprietary product quality management system have positioned us as a performance leader in the bearing industry. All our bearings are manufactured with our most advanced Bearing Technology to significantly extend the life of bearings and reduce metal-to-metal friction – saving time and operation costs. As a value-added service, we offer complete bearings fitment to maintenance solutions to our valued customers.

At SAB we have developed a proprietary product quality management system that provides for continuous improvement, emphasizing defect prevention and the reduction of variation and waste from our processes and throughout the supply chain. We provide complete engineering services and technical support – from bearing application assessment to custom product development and review. Our engineering team designs bearings and components to help our customers achieve their technical and commercial requirements.

Manufactured at our world-class manufacturing facilities in Eastern India, SAB is the most trusted name in the design to production of antifriction bearings & customized friction solutions. The company has grown steadily, delivering reliable bearings solutions and customer services. Our vast experience across various industry verticals has allowed us to evolve from leading manufacturers to complete fraction solution providers for various industry sectors. Our speed, large inventory and consistent on-time deliveries enabled us to become the most reputed bearing supplier in India in a very short span of time. Under the brand “SAB” we will have the latest manufacturing facilities to produce up to 400 mm outside diameter. The advanced technologies being adopted by the leading manufactures will be adopted. Under the Atmanirbhar and Make in India program, to make India self-reliant in critical spares, we have started working on the project.

Spherical roller bearings consist of an outer ring with a spherical raceway and an inner ring with a double-raceway, one or two cages, and one group of spherical rollers. As the center of the spherical raceway of the outer ring coincides with the center of the bearing, it makes it have the self-aligning property. Spherical roller bearings can adjust angular error or flexion caused by the angle of the axle and bearing housing or axle bend. It has a high load-carrying capacity for radial load and axle load in two directions.

Tapered roller bearings can manage both thrust and radial loads on rotating shafts and in housings. It consists of single, double, and four-row configurations. Customized geometries and engineered surfaces can be applied to these bearings to further enhance performance in demanding applications. The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surface and roller axes if projected would all meet at a common point on the main axis of the bearing. Tapered roller bearings consist of four interdependent components: the cone, the cup, the tapered rollers, and the cage.

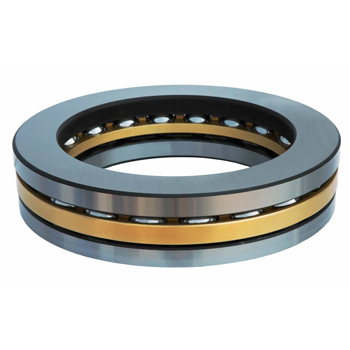

Thrust ball bearings are available in single direction thrust ball bearing and double direction thrust ball bearing. Single direction thrust ball bearing is able to accommodate axial load in one direction, while double direction thrust ball bearing is able to accommodate it in both directions. Thrust ball bearings are not suitable for applications that involve radial load or high-speed rotation. Thrust ball bearings are available in a pressed steel cage, machined alloy cage and polyamide cage.

Cylindrical roller bearings are ideal for high radial load and heavy impact. Since rollers and raceways are in linear contact they can bear high loads. Cylindrical bearings have separable inner and outer rings. Cylindrical roller bearings come in different conventional designs N, NU, NN, NNU, NJ, NF, NUP, NH. These bearings are available in Single Row Cylindrical Roller Bearing, Double Row Cylindrical Roller Bearings, and Four Row Cylindrical Roller Bearings.

Angular Contact Ball Bearing is ideal for applications that require high accuracy and good high-speed performance. These kinds of bearings are required to carry a combined load. Angular contact bearings come in different types and angles. The standard angles are 15 degrees, 30 degrees, 40 degrees.

Angular Contact Ball Bearings also come in matched pairs as back-to-back (DB), face-to-face (DF), and Tandem arrangements. Angular Contact Bearing is also available in Double Row consisting of two single-row angular contact ball bearings matched back to back with integrated inner and outer rings.

Specialized Angular Contact Ball Bearing comes in a four-point contact angle of 35 degrees consisting of an inner ring divided into two pieces.

The needle roller bearings comprise among the most compact and lightest members of the roller bearings. They offer advantages in certain situations which require less size and weight. There are several types of needle roller bearings you can select from. You can choose from a single row, double row, solid, or split cage assembly.